OUR SERVICES

ENGINEERING DESIGN

Transforming ideas into reality.

Our consulting engineers provide tailored designs that stand the test of time as well as meeting your requirements and Australian Standards. Make sure your product or system is designed and delivered seamlessly with a team of experts that work directly with a leading large-scale manufacturer.

OUR ENGINEERING DESIGN SERVICES

- Product development

- Reverse engineering

- Access and walkway structures

PRODUCT DEVELOPMENT

WHY CHOOSE NEUMANN ENGINEERING?

70+ year History

We’re part of Neumann Group—known for being industry innovators since 1948.

Efficient and Accurate

Get optimised and accurate drawings delivered efficiently. Our consulting engineers use their expertise and advanced tools to deliver high quality drafting services that are reliable, strong, and fit for purpose.

Detailed Manufacturing Drawing Packages

We develop and provide precise manufacturing drawing packages that contain all the details you need to manufacture the product.

Direct Support

Talk to the right person without the hassle. Our expert consulting engineers are always available, keeping you informed every step of the way.

Designed to Australian Standards

All our designs meet relevant Australian Standards including AS 1210, AS 1554, AS 3990, AS 4024, and AS 4991.

Certification

We offer RPEQ and CPEng certification for new and existing designs as well as statements of compliance with Australian and International Standards.

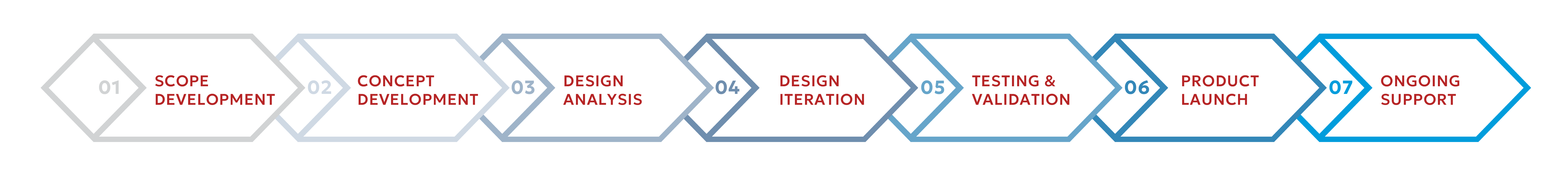

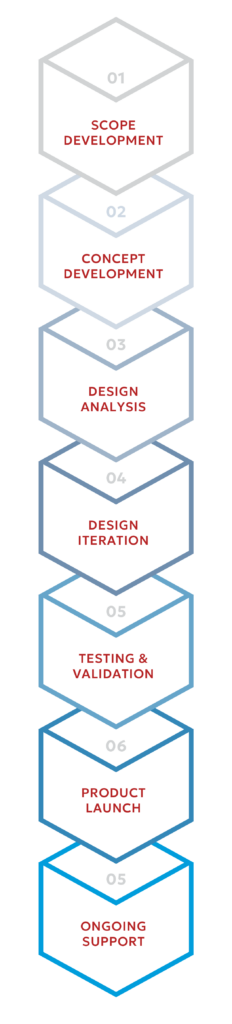

OUR HOLISTIC APPROACH

01

SCOPE DEVELOPMENT

02

CONCEPT DEVELOPMENT

03

DESIGN ANALYSIS

During this phase our consulting engineers conduct rigorous analysis and research to identify potential challenges, constraints, and opportunities for product design and engineering improvement. This includes market research, competitor analysis, and user feedback. The result is a product design that is optimised for manufacturing and ready for production.

04

DESIGN ITERATION

05

TESTING & VALIDATION

06

PRODUCT LAUNCH

The final design is turned into a physical product that’s ready to be manufactured and sold. Our consulting engineers work with you to make the manufacturing process is as smooth and efficient as possible. As part of this phase, we will thoroughly test your product and prepare it for market launch.

07

ONGOING SUPPORT

REVERSE ENGINEERING

Reverse Engineering is a powerful tool your business can use to improve or replicate your products and processes. Our consulting engineers use advanced 3D scanning and geometric analysis tools to recreate your product or process and create accurate, detailed improvements or manufacturing drawings packages.

BENEFITS OF REVERSE ENGINEERING

- Recreate discontinued products

- Modify existing OEM components to suit your application

- Develop manufacturing drawings for custom-made equipment

- Complete Geometric and Failure Analysis of components against CAD models

- Complete accurate manufacturing QA and identify defects

- Integrate machinery within a processing facility

3D SCANNING

Our design engineers are specialists in industrial 3D scanning. We use cutting-edge 3D scanning equipment and software to take precise measurements and create detailed 3D models of complex parts and structures.

WHY USE 3D SCANNING?

- Modify/Recreate accurate and detailed designs, no matter how complex

- Integrate new equipment into an existing system

- Compare CAD model to manufactured equipment (QA)

- Efficient design engineering process

- Product design optimisations

- Wear Analysis

- Analyse, optimise, and recreate existing products

- Cost-effective compared to other geometry replication systems

- Make product improvements without manual reworks

PIPING AND SLURRY

PROCESS DESIGN

Do you need a customised process design and engineering solution? We have over 25 years of experience providing piping and slurry process system design to a range of industries including mining, dredging, oil, gas, water treatment, and chemical processing.

CUSTOM DESIGN ENGINEERING

MAXIMISE EFFICIENCY AND MINIMISE COSTS

UNCOMPROMISING SAFETY

QUALITY ASSURANCE

We have a rigorous quality assurance process in place, designing your solution to the highest standards. This is done through the latest software, expert review of all designs, as well as documentation and condition and thickness testing services.

ACCESS AND WALKWAY STRUCTURES

To get from A to B safely in industrial settings you need properly planned access and walkway structures. All our fixed platforms, walkways, stairways, and ladders are designed to meet Australian Standard AS1657. Compliance with this Australian Standard helps mitigate risk and keep workers safe.

When designing access and walkway structures, our consulting engineers consider factors such as load capacity, type of access, existing structures, safety features, and accessibility.

OUR CLIENTS

Featured Projects

Design of 2 & 6 Tonne Winch Units

Design & Manufacture of Sabic Floating Electric Booster Pump

TESTIMONIALS

Lindsay Hart

NCI engaged Neumann Engineering Services to deliver a custom diesel hydraulic drum winch specifically designed for cable hauling. The machine was designed and manufactured to meet our unique requirements for speed control and tension monitoring and the team at NCI could not be happier with the level of technical expertise shown during the design process and with the high quality engineering solution provided. The winch has proven to be a reliable asset, being proven in arduous underground tunnelling conditions

LINDSAY HART

NATIONAL CABLE

Paul Watson

Neumann Engineering Services provide high quality engineered design solutions to our business that always ensure that safety aspects , operational efficiencies and ease of constructability are considered. The Engineering team adopt a professional, flexible and consultative approach in order to achieve the specifications of the project.

PAUL WATSON

NEUMANN STEEL

GET IN TOUCH

Contact us on 07 5589 9746 or through the form below.