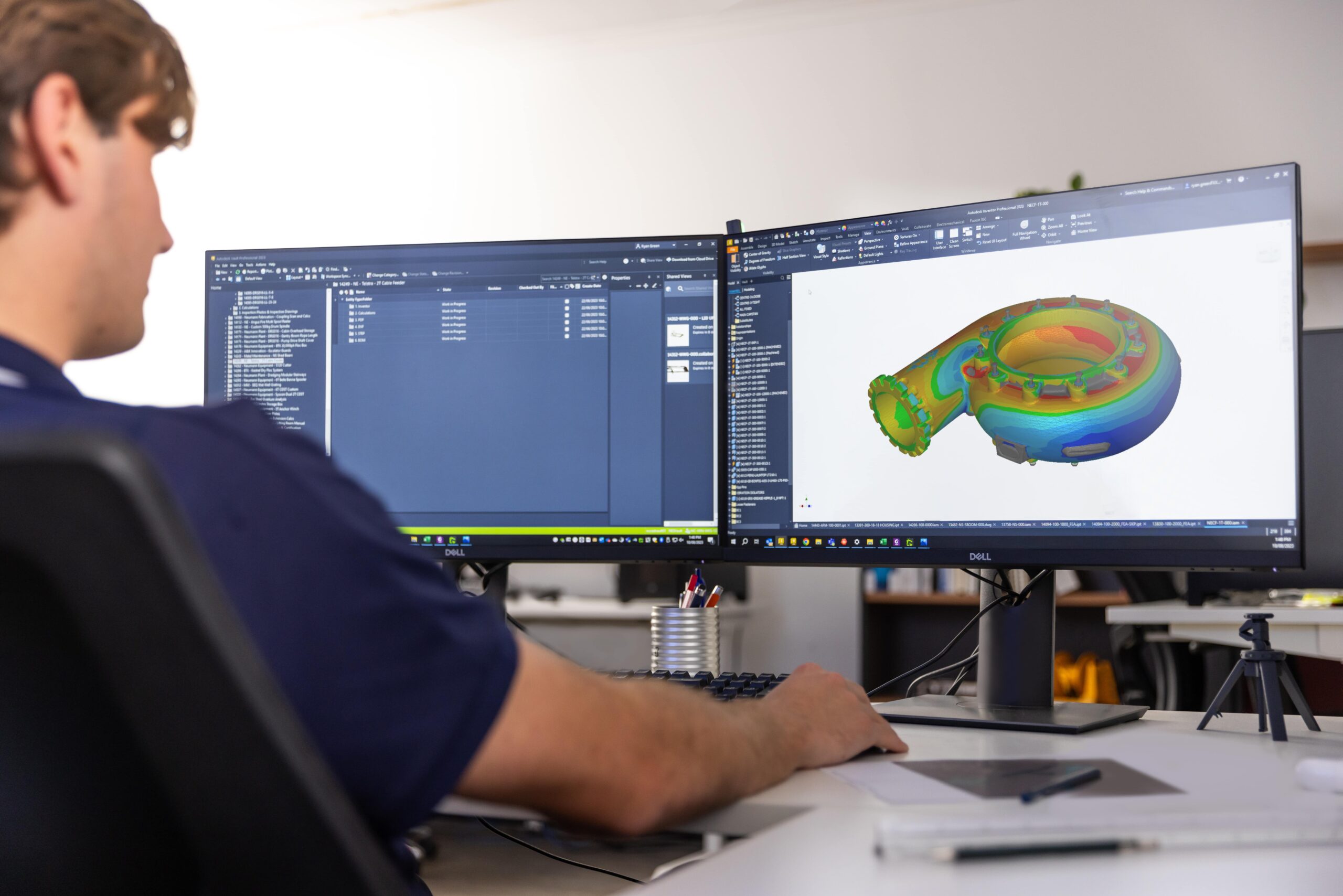

OUR SERVICES

3D Scanning

Fast, precise industrial 3D modelling.

Capture detailed mechanical and industrial models with our cost-effective, high-precision 3D scanning. Our consulting engineers are specialists in creating quality 3D models of complex parts, components, and structures using cutting-edge technology.