Projects

First aid cage design reduces lead time by 50%

Challenge

Accelerating production time while achieving strict safety & quality standards

Objectives

Developing their own first aid lifting cage design with a local company

Solution

A tailored design & complete manufacturing drawing package

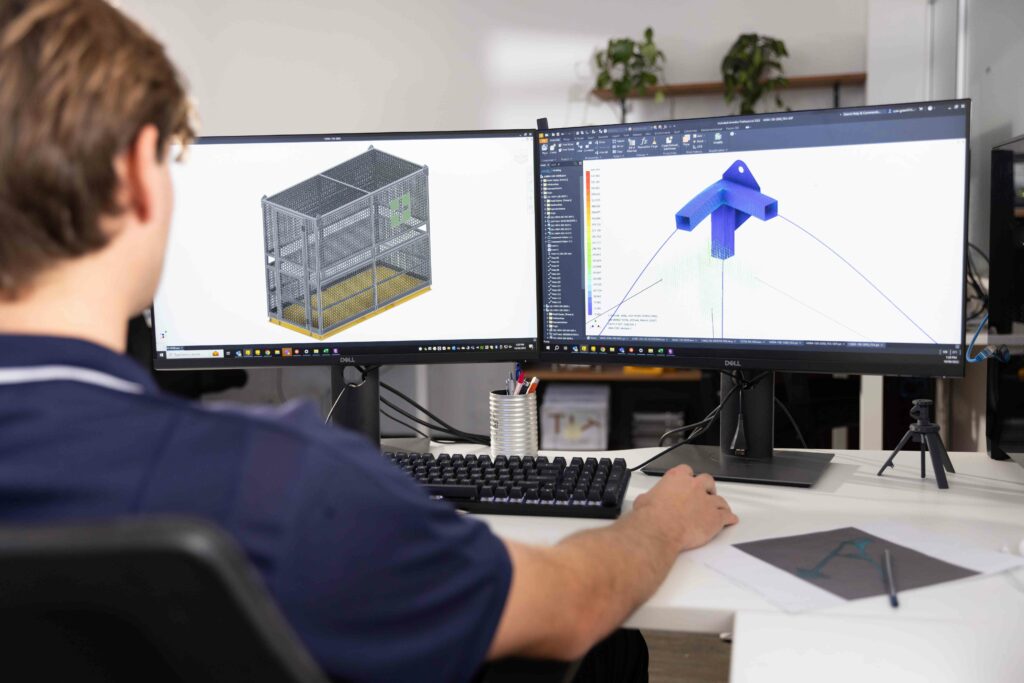

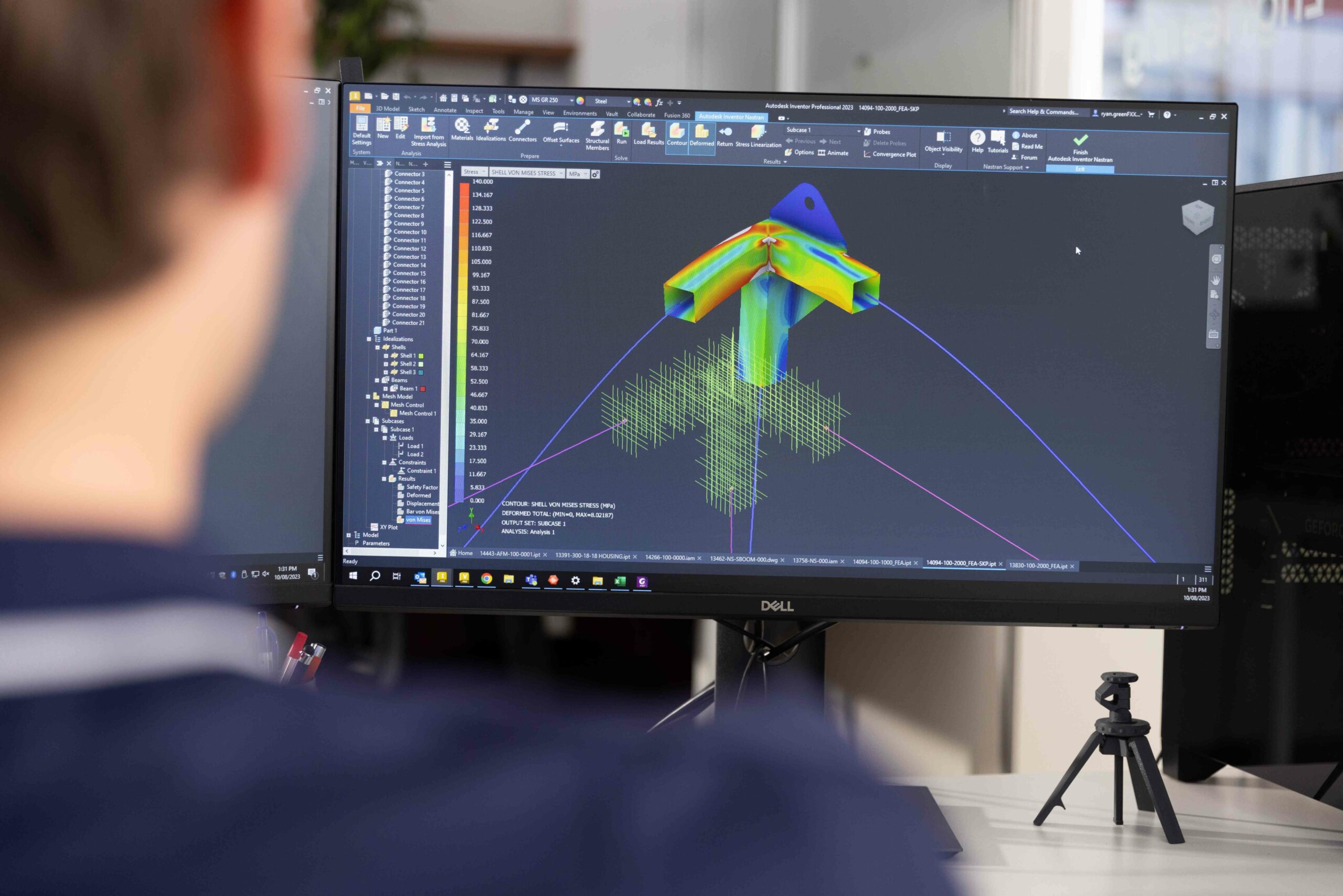

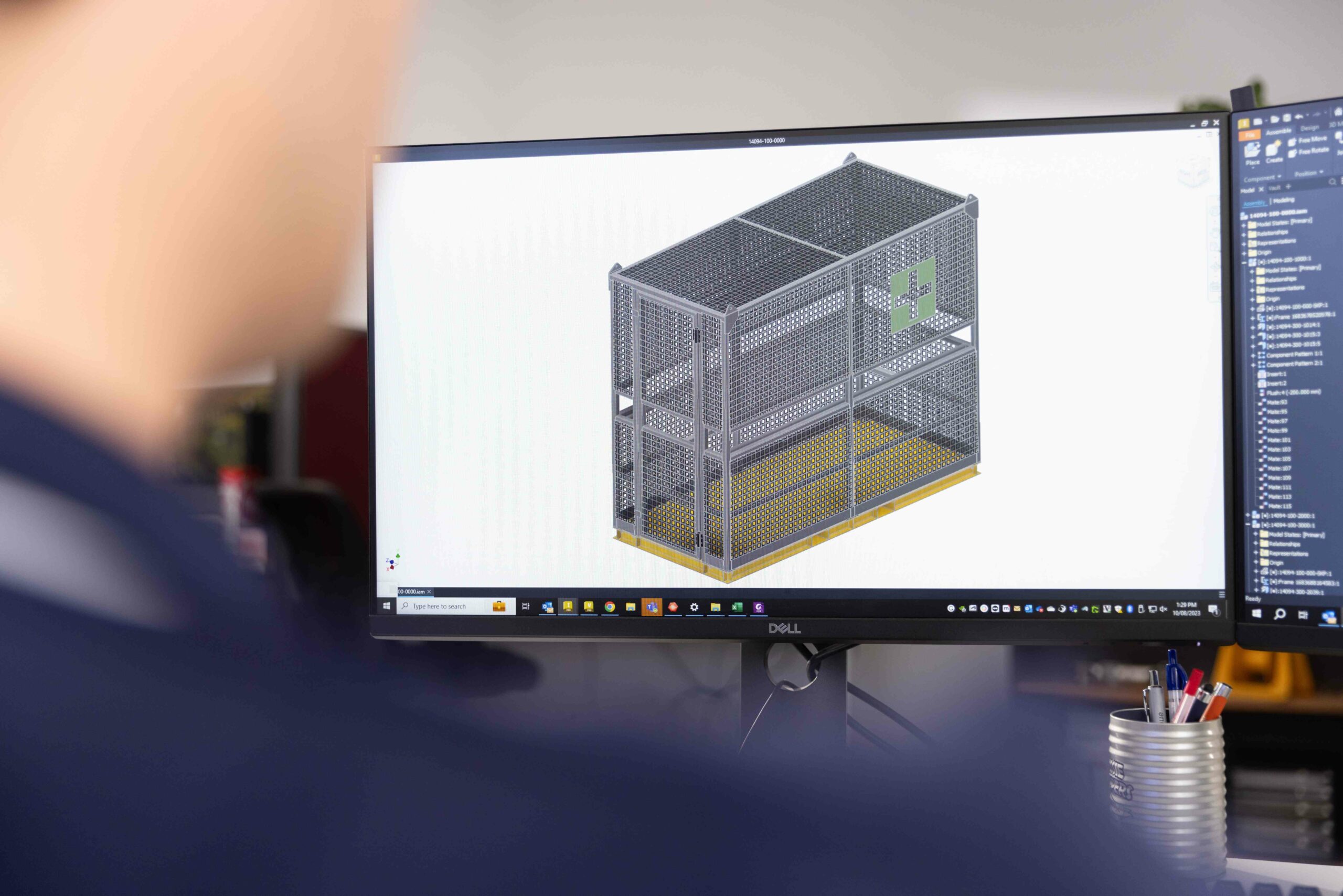

Our track record delivering complex engineering solutions and working to strict safety and compliance standards made Neumann Engineering the perfect team for the job. The new custom-designed first aid lifting cage was developed using advanced design and engineering practices, including Autodesk Inventor CAD software and Finite Element Analysis (FEA).

We worked closely with Ross Lifting to tailor the design to meet their specific requirements, including compliance with AS 1418.17 and design verification through FEA. A comprehensive manufacturing drawing package was also developed and provided by our team, giving them all the details they would need to manufacture the design now and well into the future.

Results

RPEQ certified equipment

Lead times reduced from 8 to 4 weeks

Complete proof load testing

Before shipping the equipment to Ross Lifting, we made sure it can handle at least 2X the rated capacity outlined in the requirements. This is done through a complete proof load testing onsite at Neumann Engineering.

Let’s talk about your project

Get in touch to discuss your engineering needs—whether it’s a new design, optimisation or replacement.