OUR SERVICES

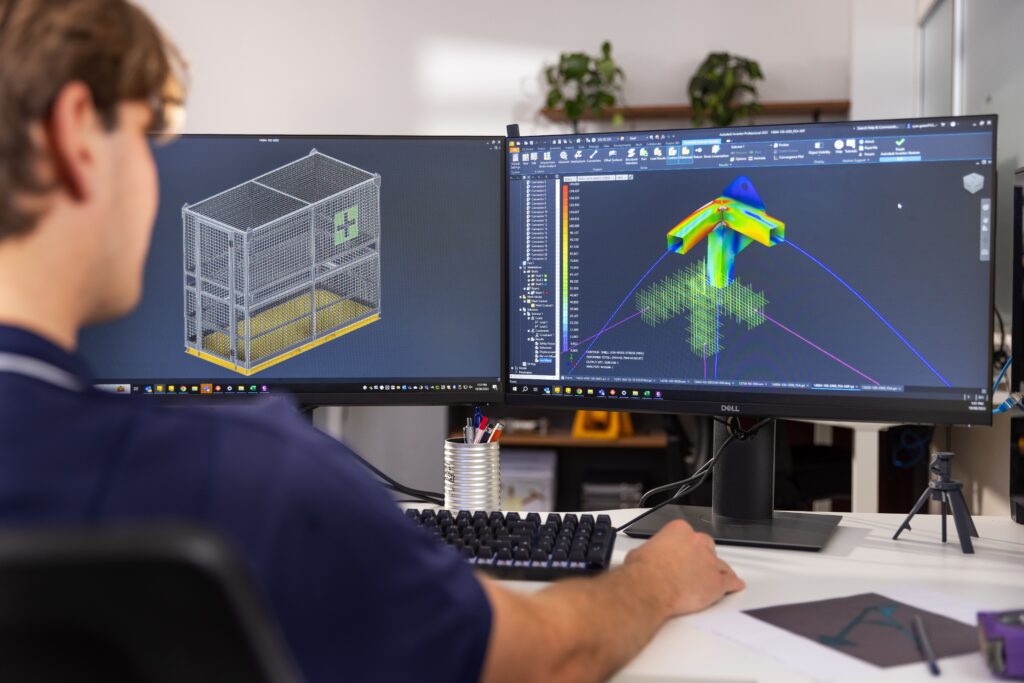

Finite Element Analysis

Simulate, analyse, and optimise your project.

Whether you need to assess a new project or perform failure analysis for an existing one, our advanced Finite Element Analysis (FEA) captures the data you need. Using cutting-edge technology and FEA expertise, we provide accurate information about how complex structures behave under real-world conditions. Through this service, we make sure your designs are safe, cost-effective, and meet compliance standards.

Optimise Projects for Real-world Conditions Before They’re Built

- Improve performance

- Achieve precise failure analysis

- Reduce warranty issues

- Decrease manufacturing costs

- Optimise material

- Meet compliance standards

What is FEA?

How Can You Use FEA Engineering?

We’ve used FEA for structural projects and products to help a variety of businesses optimise their engineering designs with powerful results. It can also be used to efficiently perform failure analysis to determine where something went wrong. FEA is an incredibly valuable tool for industries ranging from mining to marine, agriculture, industrial, and water supply.

FEA engineering is ideal for:

- Product development

- Structural and mechanical engineering design

- Manufacturing processes

- Optimising existing designs

- Failure analysis

WHY CHOOSE NEUMANN ENGINEERING?

70+ year History

We’re part of Neumann Group—known for being industry innovators since 1948.

Cutting-edge Simulation Software

We use advanced FEA technology to capture detailed information and simulate real-world conditions.

Efficient

Our industry experience allows us to rapidly and accurately complete FEA, providing the valuable information you need—when you need it.

Cost-effective

Reduce development costs and time-to-market with precise FEA at a competitive price.

FEA Expertise

Our FEA analysts are specialists in modelling, analysing, and identifying issues or opportunities in your designs.

Certification

We offer RPEQ and CPEng certification for new and existing designs as well as statements of compliance with Australian and International Standards.

OUR CLIENTS

Improve Product Performance

- Simulate failure due to cyclic loading

- Identify areas susceptible to potential cracking

- Simulate potentially dangerous or destructive load cases

- Identify design weaknesses

- Optimise product design

Achieve Precise Failure Analysis

Reduce Warranty Issues

Decrease Manufacturing Costs

Optimise Materials

Our consulting engineers use FEA to provide comprehensive results about physical stress concentration and deflection. Leveraging the power of our expertise and FEA technology, we can help you achieve more cost-effective designs and higher quality products.

Meet Local and International Compliance Standards

Finite Element Analysis vs. First Principle Calculations

- Precise physical stress results: Comprehensive result sets that show the physical stress concentration and actual deflection of the product or structure.

- Accurate safety tests: Ability to simulate potentially dangerous or destructive load cases.

- Strategic and reliable analysis: Reduce weight by eliminating material in areas where stresses are low.

- Accurately identify weaknesses: Simulate failure due to cyclic loading and identify areas susceptible to potential cracking due to fatigue.

OUR APPROACH

01

Collaborative

02

Standalone Service or as Part of Our Solutions

03

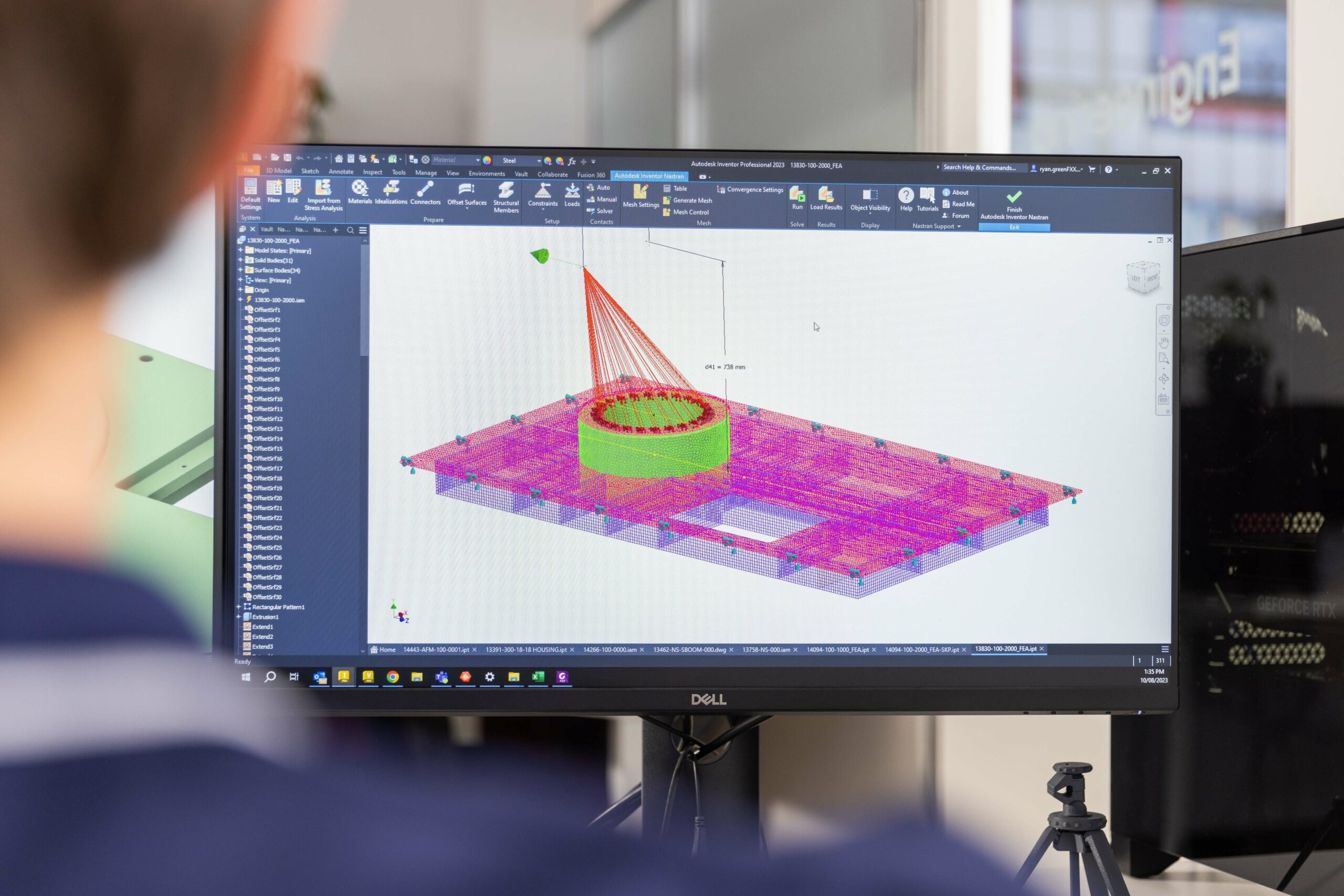

Types of FEA Tests

To gather accurate information about the various factors that could impact a product or structure, our engineers use a range of tests. These include FEA structural static analysis for scaled models, thermal engineering analysis to explore the impact of temperature variations, modal analysis to assess how vibrations will affect the design, and non-linear static analysis to see real world performance of material before and after we apply loads.

04

FEA Specialists

Our consulting engineers are specialised in FEA, optimising designs for factors such as capacity, longevity, and costs based on realistic outputs. We also use this analysis to verify compliance with the relevant Australian standards.

05

Cutting-edge Technology

Using FEA effectively relies on understanding the technology inside-out as well as the industries it is serving. Neumann Engineering invests in cutting-edge technology and a team of top-tier engineers who have worked across a range of projects and industries.

TESTIMONIALS

Lindsay Hart

NCI engaged Neumann Engineering Services to deliver a custom diesel hydraulic drum winch specifically designed for cable hauling. The machine was designed and manufactured to meet our unique requirements for speed control and tension monitoring and the team at NCI could not be happier with the level of technical expertise shown during the design process and with the high quality engineering solution provided. The winch has proven to be a reliable asset, being proven in arduous underground tunnelling conditions

LINDSAY HART

NATIONAL CABLE

Paul Watson

Neumann Engineering Services provide high quality engineered design solutions to our business that always ensure that safety aspects , operational efficiencies and ease of constructability are considered. The Engineering team adopt a professional, flexible and consultative approach in order to achieve the specifications of the project.

PAUL WATSON

NEUMANN STEEL

GET IN TOUCH

Contact us on 07 5589 9746 or through the form below.